Services

LH Dadsons Machining, LLC provides many services to help with metal fabrication and machining. Located in Hammond, Wisconsin, the company provides services for Hammond, Wisconsin and clients nationwide. What makes LH Dadsons Machining, LLC a great choice for your project is attention to detail, quality assurance, and new-age equipment. We are ISO Certified 9001: 2015.

What Services Do We Offer?

We offer a wide range of services to help with your metal fabrication and machining needs. Our services include:

- CNC machining – Our CNC machining capabilities include milling, turning, and drilling. We have both horizontal and vertical mills as well as lathes to handle your project.

- Welding – We offer both MIG and TIG welding services. Our welding capabilities include stainless steel, aluminum, and mild steel.

- Forming – We have a 100-ton press brake that can handle up to 10′ long material.

- CNC Brakes- We have CNC brakes that produce several bends in one set.

- Machining – In addition to our CNC machining capabilities, we also offer manual machining services.

- Assembly – We offer both in-house and outsourced assembly services.

- Finishing – We offer a variety of finishing services, including powder coating, anodizing, and plating.

Our Offsite Services

In addition to our on-site services, we also offer many offsite services. We have a team of highly trained and experienced engineers who can come to your site to assess your needs. We can then provide you with a quote for our services.

Our Quality Assurance

At LH Dadsons Machining, we are committed to providing our customers with the highest quality products and services. Our services don’t just begin or end with our production.

We have many services for various projects. A project is never complete without quality control. The company makes a commitment to have less than 1% rejected projects. Once you receive a project from us, it has gone through several checklists.

Our quality care in Hammond, WI, involves documentation, training employees in our quality system, and extensive planning. We also have an on-site quality lab where we can test products to ensure they meet our high standards.

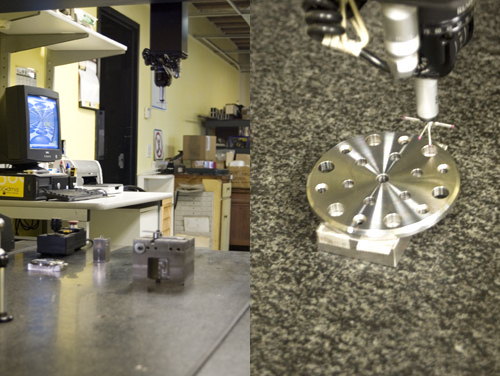

Precision CNC Machining

Key Benefits & Capabilities

- Turning: 15″ Dia. Chucks by 70″ long, Bar capacity to 3″ dia.

- Milling: 30″ x 60″ x 28″ with up to 5 axis, 40 & 50 taper some with coolant thru spindle.

- Programming: CAD/CAM programming, file transfer / solids preferred

ASSEMBLY

- Your project shipped to you complete.

INSPECTION

- Fully programmable CMM.

SAWING

- Up to 11″ rd.

STAMPINGS : SHORT TO MEDIUM RUN

Key Benefits & Capabilities

- Deep Draws: Draws to 10 x Dia.

- Semi Compounds: Many jobs run in one tool

- CNC Brakes: Multiple bends in one set-up

CNC TURRET PRESSES, BRAKES, WELDERS

Key Benefits & Capabilities

- CNC Turret Presses: (5) CNC turret presses (1) Amada press brake

- Low Cost Tooling: In house semi permanent tooling keeps cost down & revisions easier in most cases

- Competitive Pricing: With state of the art technology, we handle the part less

PLATING & PAINTING

Key Benefits & Capabilities

- Powder Coating: Any powder coating needs in any color you require

- Plating Sources: Any finishing needs your parts may require

- Finished Parts: Your parts arrive on your dock requiring no additional services

CASTING & FORGING

QUALITY CONTROL AND INSPECTION

We handle even the toughest of manufacturing challenges. Dadson’s ensures compliance to the quality policy by fulfilling the following objectives:

- To improve operational efficiency

- To keep rejects below 1%.

- To improve ability to meet customer commitments.

- To ship products to our customers, defect free and on time.

- To have our departments work as one through the sharing of information.

- To continually reduce costs to our customers.

- To maintain a work environment that encourages employee participation and progress.

Quality Documentation

LH Dadsons Machining, LLC has adopted a documented Quality System as a means of ensuring product conformity to specified requirements. These documents begin with this Quality Manual, which contains an overview of our Quality Procedures. Quality Procedures are supported by working documents that are referenced within respective procedures.

Quality Procedures

Quality Procedures are to provide employees with instructions on the performance of tasks to support our Quality System. These procedures were developed as a joint venture between management and qualified employees to meet the requirements of our customers. All employees at LH Dadsons Machining, LLC are responsible for implementing the Quality System to achieve total customer satisfaction.

Quality Planning

Quality Planning is a continuous activity at LH Machining, Inc.

These planning activities include, but are not limited to:

- Internal Audit Plans

- Employee Training Plans

- Production Plans (as outlined in Shop Router)

- Inspection Plans (In-Process & Final Inspection Sheets)